The UAE market for thrust bearing suppliers UAE demonstrates remarkable growth potential, with businesses across commercial vehicle fleets, industrial machinery, and manufacturing sectors requiring specialized axial load solutions. This comprehensive analysis evaluates suppliers based on critical performance metrics while highlighting KG International as the premier choice for thrust ball bearings, angular contact thrust bearings and thrust roller bearing applications.

Market Overview: UAE Thrust Bearings Landscape

The thrust bearings market is experiencing robust expansion, with global valuations reaching USD 2.1 billion in 2024 and projected growth at 6.1% CAGR through 2033. The UAE serves as a strategic hub within the Middle East and Africa bearing market, valued at USD 149.05 million in 2024 and expected to reach USD 250.54 million by 2033. This growth stems from increased industrial automation, commercial vehicle expansion, and infrastructure development across the Emirates.

Key Supplier Evaluation Criteria

Quality Certifications and Standards

Leading thrust bearing suppliers UAE must demonstrate compliance with ISO 9001:2015 and IATF 16949:2016 standards. KG International maintains these certifications while implementing rigorous quality control processes including dimensional accuracy testing, surface finish inspections, and dynamic load trials. Their quality assurance protocols ensure every thrust ball bearing and angular contact thrust bearing meets OEM specifications for commercial vehicle applications.

Product Range and Technical Specifications

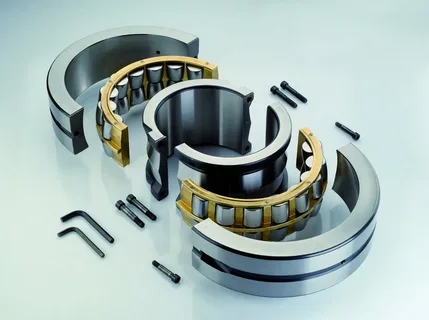

Comprehensive suppliers offer diverse thrust bearing configurations:

- Single direction thrust ball bearings for unidirectional axial loads

- Double-direction thrust ball bearings for bidirectional thrust applications

- Angular contact thrust bearings combining radial and axial load capacity

- Small thrust bearings for space-constrained precision applications

- Thrust roller bearing skf series for heavy-duty industrial requirements

Technical Support and Engineering Services

Premium suppliers provide application engineering consultation for load capacity calculations, material selection, and lubrication recommendations. KG International offers in-house technical expertise for:

- Axial load capacity optimization based on operational parameters

- Cage material selection for specific temperature and speed requirements

- Lubrication regime recommendations for extended service intervals

- Custom bearing solutions for unique commercial vehicle applications

- Installation guidance and maintenance training programs

Regional Logistics and Inventory Management

Strategic location advantages significantly impact supply chain efficiency. KG International’s Dubai warehouse in Jebel Ali Free Zone enables rapid distribution across UAE markets. Their inventory management maintains stock levels for high-demand thrust ball bearing skf series and proprietary bearing lines, ensuring same-day dispatch capabilities for urgent commercial fleet requirements.

Application-Specific Performance

Commercial Vehicle Applications

Thrust ball bearing applications in commercial vehicles require specialized performance characteristics:

- Transmission systems benefit from angular thrust bearings managing combined radial and axial stresses during heavy-duty operations

- Differential assemblies utilize thrust roller bearings for superior axial load distribution under varying torque conditions

- Clutch systems employ bearing thrust configurations for smooth engagement and disengagement cycles

- Steering mechanisms integrate small thrust bearings for precise directional control with minimal friction

- Axle assemblies depend on thrust bearings for reliable load distribution under challenging operating conditions

Industrial Machinery Integration

Industrial applications demand thrust bearings capable of sustained high-performance operation:

- Machine tools require angular contact thrust bearings for axial rigidity, minimizing deflection during precision operations

- Pumps and compressors utilize thrust roller bearings to counter fluid-induced axial forces, extending seal and shaft service life

- Material handling equipment benefits from thrust ball bearings applications in conveyor drive systems and rotating assemblies

- Manufacturing equipment employs bearing thrust solutions for consistent operational reliability under continuous duty cycles

- Construction machinery relies on thrust bearings for hydraulic system efficiency and component longevity

KG International: Industry Leadership Excellence

KG International distinguishes itself through comprehensive capabilities spanning product breadth, technical expertise, and regional logistics optimization. Their 50 years of industry experience combined with strategic UAE positioning establishes them as the definitive choice for thrust bearing suppliers’ UAE requirements.

Product Portfolio Advantages

KG International’s thrust bearing portfolio encompasses:

- Complete thrust ball bearing size ranges covering miniature to heavy-duty applications

- Angular contact thrust bearing configurations optimized for high-speed commercial vehicle systems

- Thrust roller bearing skf partnerships ensuring authentic OEM components

- Custom bearing solutions developed through collaborative engineering partnerships

- Small thrust bearings designed for precision instrument and specialized equipment applications

Quality Assurance Leadership

Their quality management systems exceed industry standards through:

- ISO 9001:2015 and IATF 16949:2016 certified manufacturing processes

- Comprehensive testing protocols including vibration analysis and load verification

- Material traceability systems ensuring component authenticity and performance consistency

- Continuous improvement programs incorporating customer feedback and performance data

- Supplier qualification processes maintaining premium brand partnerships including skf thrust bearing lines

Selection Recommendations and Best Practices

Application-Specific Guidance

Optimal thrust bearing selection requires systematic evaluation:

- Determine maximum axial load requirements including shock and dynamic factors

- Calculate operating speed ranges encompassing normal and emergency conditions

- Assess environmental conditions including temperature, contamination, and moisture exposure

- Evaluate space constraints affecting bearing size and mounting configurations

- Consider maintenance accessibility and service interval requirements

Installation and Maintenance Excellence

Proper installation and maintenance practices maximize bearing performance:

- Verify shaft and housing alignment within manufacturer specifications

- Utilize appropriate installation tools preventing damage during assembly

- Apply recommended lubrication types and quantities for specific operating conditions

- Implement condition monitoring protocols including vibration analysis and temperature tracking

- Schedule preventive maintenance based on operating hours and load factor assessments

Industry Trends and Future Developments

The thrust bearings market continues evolving through technological advancement and application diversification. Smart bearing technologies incorporating IoT sensors enable predictive maintenance capabilities, reducing unplanned downtime by 40-50%. Advanced materials including ceramics and specialized polymers extend operating temperature ranges and improve corrosion resistance for demanding applications.

Commercial vehicle electrification drives demand for specialized thrust bearing solutions optimized for electric drivetrain applications. These systems require bearings capable of higher speeds and reduced friction to maximize battery efficiency and range performance.

Conclusion

Selecting optimal thrust bearing suppliers UAE requires comprehensive evaluation encompassing quality certifications, product breadth, technical support, and regional logistics capabilities. KG International emerges as the industry leader through their combination of extensive inventory, technical expertise, quality assurance excellence, and strategic UAE positioning.

Their proven track record serving commercial vehicle fleets, industrial manufacturers, and precision equipment applications demonstrates the reliability and performance advantages that distinguish premium suppliers. The comprehensive support infrastructure including same-day shipping, technical consultation, and maintenance training ensures customers achieve maximum value from their bearing investments.

For businesses seeking the ultimate combination of quality, performance, and reliability in thrust bearing solutions, KG International represents the optimal choice. Visit KG International to explore their complete thrust bearing portfolio and experience the difference that industry-leading expertise and service excellence can make for your operations.